Creek Manufacturing E Series LOW VISCOSITY (LV2) VIVID BULK DTG Ink (CLEARANCE SALE)

- Regular price

-

$59.99 - Regular price

$125.00 - Sale price

-

$59.99

Couldn't load pickup availability

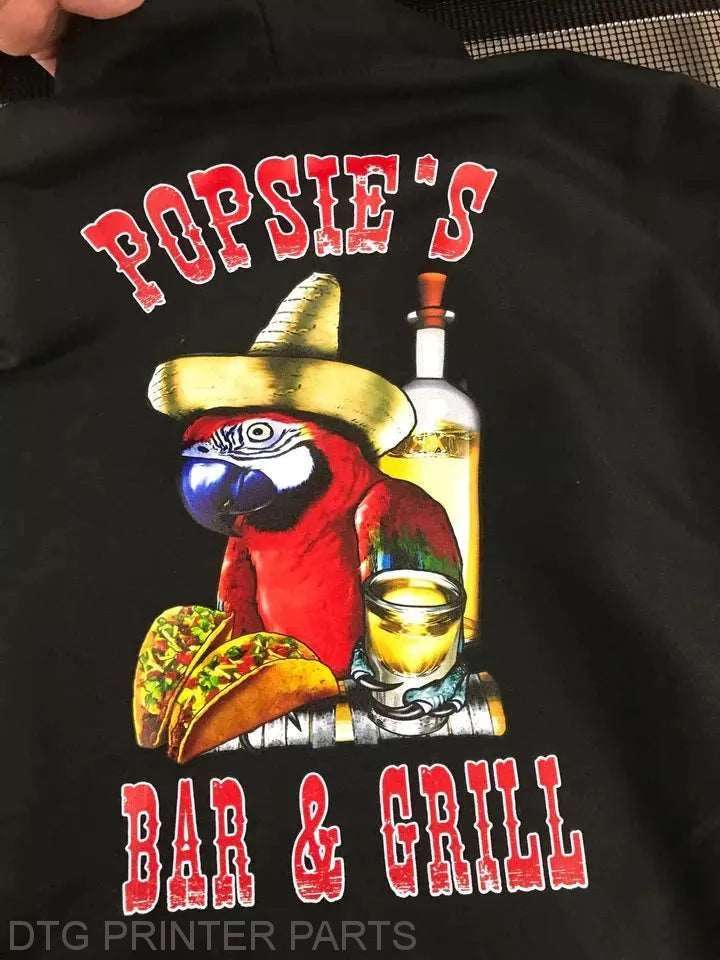

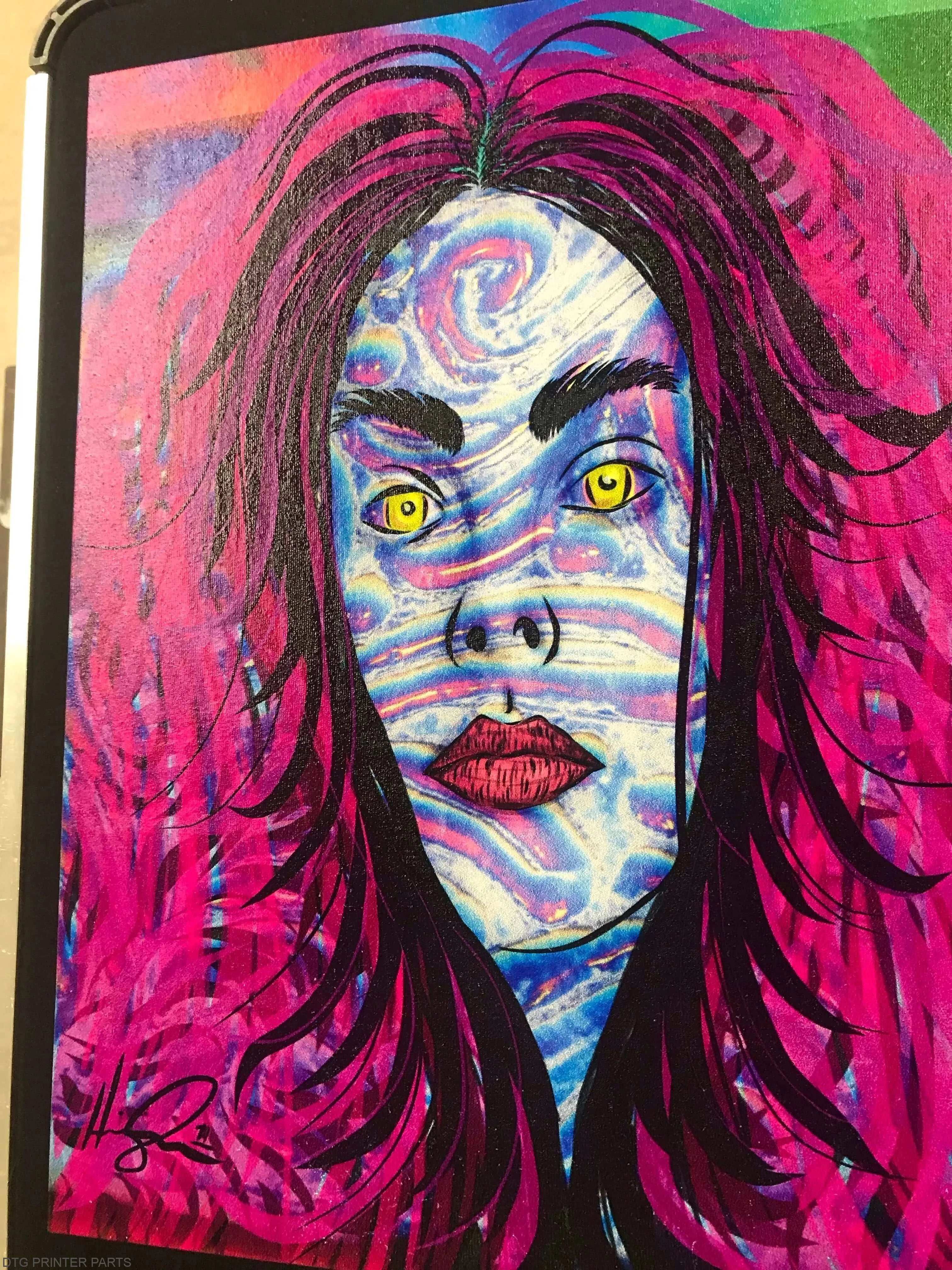

Fast Shipping: Get your hands on the vivid bulk DTG ink in just 2 days! The liter pack contains white ink only, and will be shipped most economically along with other items.

High Washability: Our bright white ink and CMYK ink both have excellent washability, ensuring long-lasting, vibrant prints that you'll be pleased with.

Easy Directions: Cure CMYK only prints at 325°F/162°C for 60 seconds at a minimum. For W+CMYK prints, cure at 338°F/170°C for 130 seconds. Poly/Cotton/Rayon blends work well, achieving better results when used with a conveyor/heat press combination. Use low to medium pressure for best results.

- If you are converting from other inks, you will NOT need to flush your current ink set out.

- SDS sheets are available upon request for your convenience.

- *Bottle Sizes may vary during covid. Bottle sizes are approximate and can vary depending on settling. Results are not guaranteed and will depend on machine settings/environment. If using for DIRECT TO FILM you should test before purchasing large volumes.

Printer Compatibility:

- Epson Repurposed DTG's using a DX5 / DX7 head (See Chart Below)

- 5113 Print head

DTG Printer Compatibility

Since the new E-SERIES inks are being released for all of the Epson® repurposed printers you might be wondering if you will be able to use them. Some of the printers include (but not limited to):

|

This DTG ink is recommended for use in Epson based DTG printers with a DX5, DX7, or 5113 head. For printers bigger than 12 inches wide in print area, it's best to use 35% humidity or higher for optimal performance. Please note that we are not affiliated with Epson or the companies listed above with respective printers in the compatibility chart. The Creek E Series Direct-To-Garment Ink is for repurposed Epson DTG's and is compatible ink (Non OEM). and any company listed above, such as is a registered trademark of the respective company. User assumes liability in using this product.

Warning: Work in a well-ventilated area and use protective equipment (including masks and gloves) when working with specialty printing and curing products and processes such as dtg printers, as fumes and processes may be hazardous. We highly recommend the use of a fume extractor when working with DTF powder in addition to good ventilation and filtration in your work area. The use of all specialty ink printing equipment and supplies such as inks, chemicals, powders etc. are at the sole risk of the user.

DISCLAIMER

NO WARRANTY OR IMPLICATION OF WARRANTY FOR THIS PRODUCT. SINCE THE CONDITION OF HANDLING IS BEYOND OUR CONTROL, WE ASSUME NO LIABILITY FOR LOSS OR INJURY RESULTING FROM THE USE OR THE INFORNMATION HEREIN. ALL CHEMICALS MAY PRESENT UNKNOWN HEALTH HAZARDS AND SHOULD BE USED WITH CAUTION. SAFE USE OF THIS PRODUCT IS THE RESPONSIBILITY OF THE USER. USER MUST TEST TO DETERMINE SUITABILITY BEFORE USING. REFER TO SDS SHEETS FOR ADDITIONAL INFORMATION/HANDLING.

WARNING: This product may expose you to chemicals which are known to the State of California to cause birth defects or other reproductive harm. This warning is posted because of the legal requirements of the State of California. For more information, please visit www.p65Warnings.ca.gov.

California Proposition 65

This material is not known to contain any chemicals currently listed as carcinogens or reproductive toxins. For more information go to www.P65Warnings.ca.gov

100%SECURED

SHIPPING

100%QUALITY PRODUCTS

FREESHIPPING WITH MINIMUM ORDER

TRUSTEDONLINE

SELLER

Creek Manufacturing E Series LOW VISCOSITY (LV2) VIVID BULK DTG Ink (CLEARANCE SALE)

- Regular price

-

$59.99 - Regular price

$125.00 - Sale price

-

$59.99